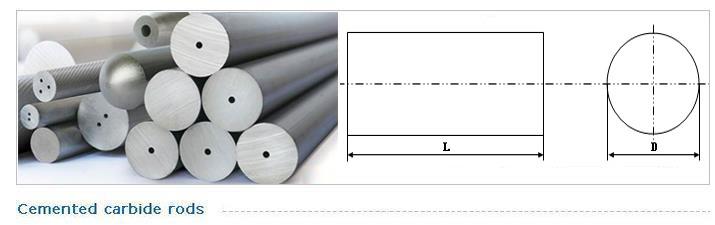

Tungsten Carbide Rod is mainly made of WC and Co by powder metallurgic method processing. ZHUZHOU LIZHOU CEMENTED CARBIDE CO., LTD main provide the Solid Carbide Rod and carbide tube, which production under CIP production with good density and higher bending strength ,

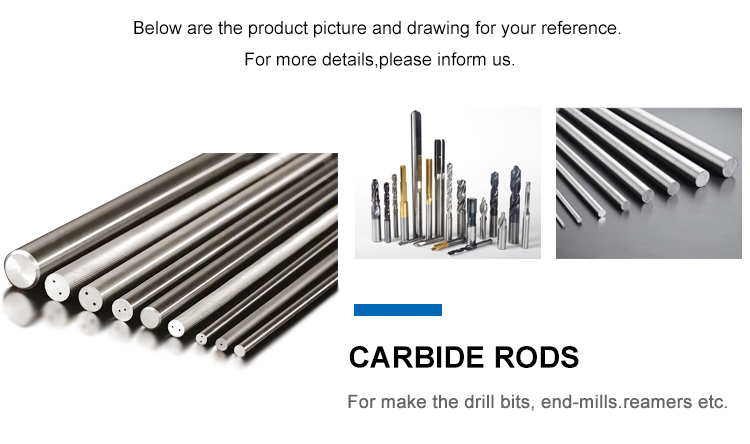

Tungsten carbide rods are application in make the drill bits, end-mills, reamers ,automobile special cutters, printed circuit board special cutters, engine special cutters, Horologe processing special cutters, integral vertical milling cutter, graver and etc. Besides, they can bu used for making of cemented carbide stamping head, Core bar and perforation tools. Both sintered blanks and ground tungsten carbide rod are supplied.

Now we have two grade for your option, LX25 (make tools material HRC<=55 ) and LBC25 (make tools material HRC>=55)

Recommended grade:

Application:

rade | Grain Size(µm) | Density (g/cm³) | Hardess (HRA) |

TRS(N/m㎡) | Fracure Resistane ((Kic),MPa.m^(1/2) | USAGE |

LBC15 | 0.8 | 14.42 | ≥91.5 | ≥4100 | 10.7 | The most classic grade for market more than hundred tons sales. With it's excellent impact resistance and strong versatility, it's recommended for cast iron, and aluminum allory and the cutting tool material which HRC<50 . |

LBC25 | 0.6 | 14.13 | ≥92.5 | ≥4200 | 10.8 | thas the good wear-resistance and high toughness with more versatiity.it is suitable for processing carbon steel,diessteel,316stainlesssteel,ect.we are recommended to manufacturing semi finishing and finishing mill cutterswhich cutting tool material HRC<60 |

LBC15S | 0.7 | 14.42 | ≥91.8 | ≥4200 | 10.8 | It has the good wear-resistance, high toughness and more versatility.it's situable for rough and finish process of steel, stainless steel and aluminum alloy,which is recommended for cutting tool material HRC<52. |

LBC25S | 0.6 | 14.13 | ≥92.8 | ≥4500 | 12 | It is recommended for rough and finishing process of stainless steel, dies steel and super hard aluminum alloy, heat resistant alloy and other cutting tool material which HRC<55. |

LBC09 | 0.5 | 14.6 | ≥93.2 | ≥4000 | 9 | End mill for High hardness material are recommended for high wear-risistance material such as hardened steel, graphite, aluminum alloy and composite material. |

LBC10 | 0.3 | 14.4 | >=93.6 | ≥4200 |

| Ultra fine grain size High wear resistance end mill and engraving tools are recommended. Situable for cutting PCB and Plastic. |

Avaliable Size:mm Unground and Ground to h5/h6

OD(mm) | L(mm) |

¢3.0~¢40 mm | 310/330 |

We are accept the size as per the customers’ requirement.